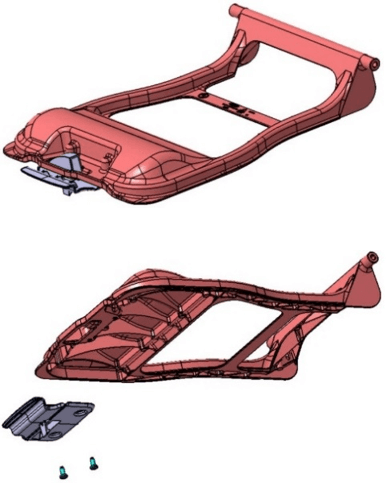

F250 Seat Composite Cushion Frame

Return to SolutionsThe Challenge

Replace magnesium die cast, a known light weight material, with a plastic alternative at a lower cost point with greater flexibility in terms of design and cost while satisfying all Safety and Crashworthiness requirements.

Our Solution

Royal technologies worked closely with Ford, the resin supplier and tool shops to develop an industry first application of a composite material into a 2-point pivoting structural set cushion frame. This new solution provided a significant cost and weight reduction, improved the carbon footprint as well as earned Ford an SPE award and 4 US Patents.

%

Cost vs. Original Cost

%

Reduction in Weight

Technical Details

Previous Situation

- Magnesium die cast cushion frame.

- Existing Magnesium tooling required constant maintenance

- Magnesium part requires secondary de-flash operation

- Magnesium part requires specialty fasteners to attach to seat structure and plastic latch

- Magnesium as a material is more expensive when compared to a composite plastic.

- Magnesium applications worldwide have significantly larger carbon footprint compared to plastic composites.

Our Solution

- First industry application of 40% LF GF-PP composite material in a combination 2-point pivoting structural seat cushion frame

- Meets or Exceeds all NHTSA and FMVSS requirements

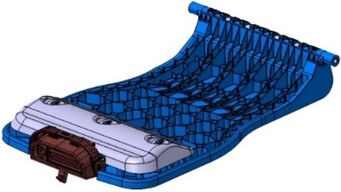

- Improved crashworthiness using energy absorbing EPP anti-submarine block

- Meets Jounce durability, Console System Static and Cycle Loads

- Eliminated use of specialty fasteners for magnesium thread forming

- Offers an open architecture for future add-on features such as:

- Cargo hooks, Straps, and Unique Flexible Storage Features

- Inter-changeable (lock vs. non-lock) latch provides customer personalization