Aeron Chair Arms

Return to SolutionsThe Challenge

Herman Miller’s Aeron chair is a legend, as is the company’s commitment to environmental sustainability. From a green perspective, however, the chair’s armrests were a weak point. Herman Miller asked us to propose a cost competitive, locally produced environmentally friendly alternative to injection molded PVC.

Our Solution

Royal Technologies developed an armrest from a self-skinning polyurethane foam, eliminating the use of PVC entirely while at the same time simplifying production and cutting both the cost and weight of the finished component by roughly 20%.

Results

Aeron Chair Achieves MBDC Silver Certification

Herman Miller, Inc., is again demonstrating its commitment to environmental sustainability with one of its most iconic and successful seating designs–the Aeron chair…. This renowned design now further distinguishes itself by receiving McDonough Braungart Design Chemistry (MBDC) Cradle to Cradle Silver certification for environmentally friendly design. “In Aeron’s case, we particularly addressed the use of PVC in the arm pads. After significant research and collaboration with a new, minority-owned supplier, our ambition for a PVC-free, polyurethane arm pad is now a reality.”

%

Cost vs. Original Cost

%

Weight Reduction

Technical Details

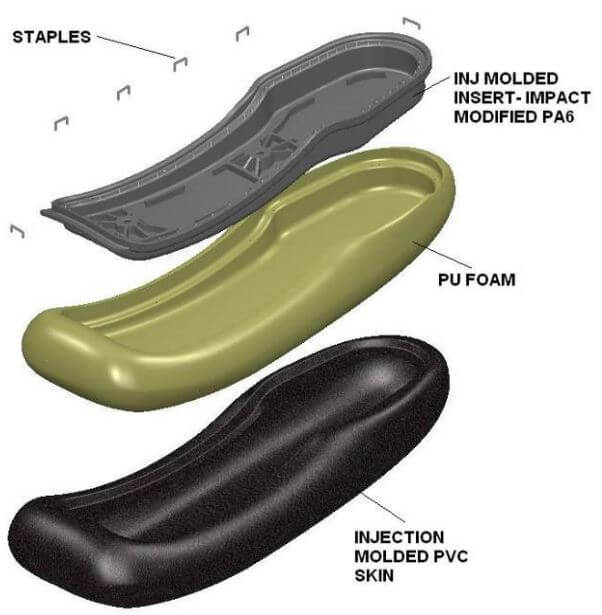

Previous Situation

- Injection molded PVC skin.

- PU foam molded around High Impact Nylon.

- Multiple staples to secure skin to foam.

- Environmentally unfriendly due to PVC.

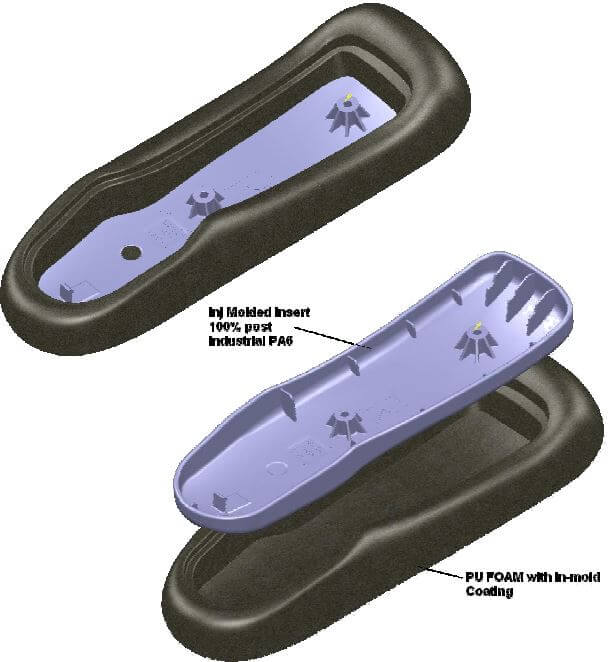

Our Solutions

- Integral skin PU foam

- In-mold coating

- 100% Post Industrial Regrind Nylon used for the insert.

- Eliminated all post assembly operations (no need for any staples)