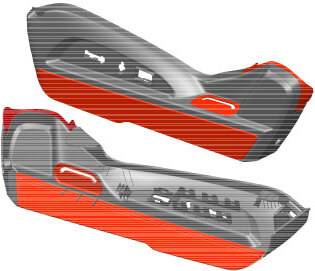

Automotive Side Shield

Return to SolutionsThe Challenge

Designing for the automotive industry means navigating a minefield of complex challenges and requirements. One manufacturer approached us with a problem: their prototype side seating shield was expensive to produce and difficult to manufacture—they needed an alternative.

Our Solution

Our prototype, though slightly heavier, was less expensive to produce and far easier to assemble. In addition, because of the material and manufacturing processes we employed, our prototype allowed more flexibility for aesthetics.

%

Cost vs. Original Cost

%

Weight Reduction

%

Increase in Functionality

Technical Details

Previous Situation

- Multishot Injection mold part design.

- 3 distinct areas for 2nd shot elastomer.

- Extremely complex and expensive mold.

- Gating would need to be 3 zone sequential valve gating.

- Actual mold design feasibility was in question.

- High tool maintenance cost.

- Poor shutoff conditions.

Our Solution

- Top closeout and main shield molded as a simpler 2 shot part.

- Lower skirt and seatbelt opening combined into one simple, Open and Shut mold with living hinge.

- Third part (simple, open and shut mold with living hinge) designed to aid retention of heat stake operation.

- InfraStake process used for assembly.

- Assembly is performed at molding machine to utilize labor.