The Challenge

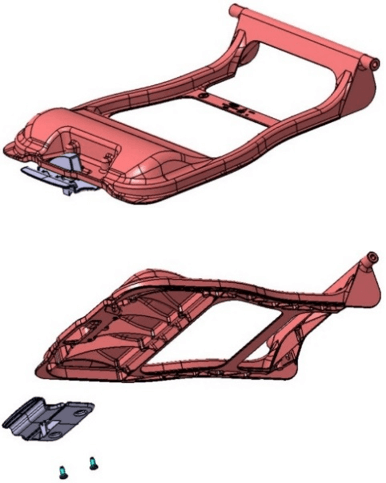

Replace magnesium die cast cushion frame, a known light weight material, with an even lighter plastic alternative at a lower cost point with greater flexibility in terms of design and cost while satisfying all Safety and crash-worthiness requirements.

- Existing Magnesium tooling required constant maintenance

- Magnesium part required secondary de-flash operation and specialty fasteners to attach to seat and latch

- Magnesium material is more expensive when compared to a composite plastic

Our Solution

Royal technologies worked closely with Ford, the resin supplier and tool shops to develop an industry first application of a composite material into a 2-point pivoting structural seat cushion frame. This new solution provided a significant cost and weight reduction, improved the carbon footprint as well as earned Ford an SPE award and 4 US Patents.

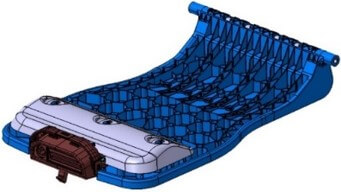

- First industry application of 40% LF GF-PP composite material in a combination 2-point pivoting structural seat cushion frame

- Meets or exceeds all NHTSA and FMVSS requirements

- Improved crash-worthiness using energy absorbing EPP anti-submarine block

- Meets Jounce durability, Console System Static and Cycle Loads

- Eliminated use of specialty fasteners for magnesium thread forming

- Inter-changeable (Lock vs. non-lock) latch provides customer personalization